Sulfur

For more than three decades, there has been one name the sulfur industry has come to rely on for expertise in sulfur forming, processing and handling: Devco. Matrix PDM Engineering acquired Devco in 2016 and continues this same legacy of expertise and leadership.

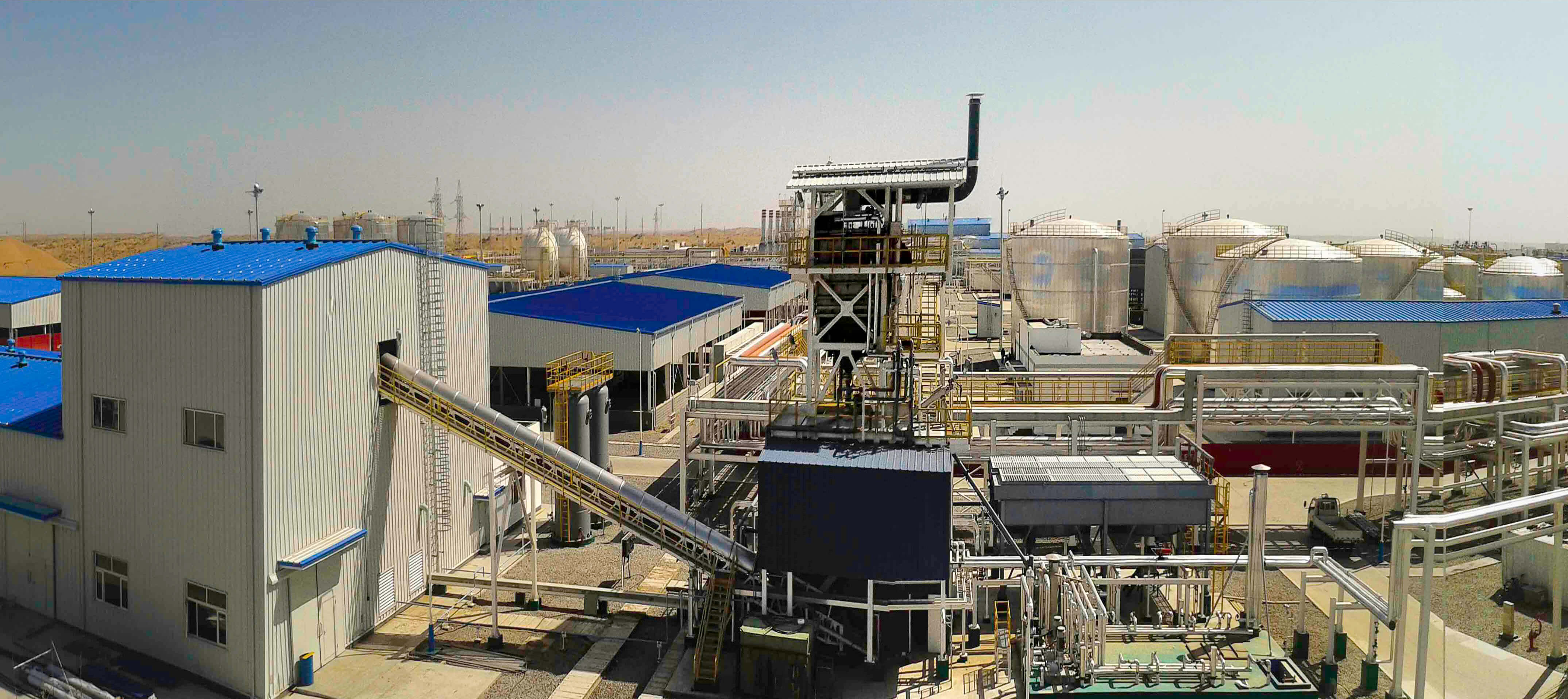

Today, Matrix PDM Engineering provides the expertise and flexibility for producers and consumers across the dynamic sulfur supply chain and offers both operating and EPC companies seamless project execution from sulfur recovery units (SRUs) to sulfur loading that is unrivalled in the world.

Our core capabilities include sulfur prilling, sulfur forming (wet and dry technologies), bulk handling, facility design, sulfur storage and handling, sulfur blocking (long-term storage), sulfur melting, conceptual engineering, and operations expertise.

Matrix PDM serves the sulfur industry in multiple capacities including:

- Sulfur forming

- Sulfur melting

- Sulfur recovery

- Modularization

- Sulfur block pouring

- Sulfur asphalt

- Sulfur purification

Sour Gas and other Gas Processing Capabilities

In sour gas and other gas processing capabilities, Matrix PDM Engineering brings expertise in cryogenic gas separation, amine treating, and stabilizer liquids units. The company also specializes in the modular delivery of SRUs. We have managed projects and provided balance of plant engineering around both standard gas plants and specialty processing facilities in the United States, Asia and the Middle East.

Sulfur Forming Technology

Matrix PDM Engineering’s proprietary Devco II sulfur forming technology provides high capacity operation, consistent product sizing, and meets all moisture requirements for international trade. Today, these units are being commissioned in Saudi Arabia and Alberta, Canada and remains the technology of choice for safe sulfur forming operation in the United States, China and Saudi Arabia.

Materials Handling

Our engineers and designers bring years of experience with sulfur and other similar bulk commodities such as grain and cement, as well as handling systems in mining and minerals operations. Our capabilities can range from FEED to full project execution.

Click here to learn more about what we design for the sulfur market.