CEMEX – Cement Facility DCS Upgrade

Location: New Braunfels, TX

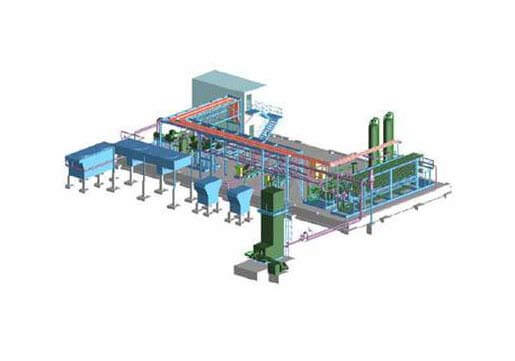

Matrix PDM provided design, engineering and commissioning support services for a complete retrofit, as well as replacement of existing obsolete control system hardware for an entire cement production line.

The facility planned to double its capacity through a new kiln line expansion, and the existing Bailey Infi90 DCS wasn’t capable of accommodating the additional I/O required.

3+

miles of trunk wiring

33

individual ControlLogix subpanel assemblies

4

ControlLogix PACs

Scope of Work

- Tight start-up timeline and successful on-time completion

- Selection of ControlLogix PA C platform, supported by Rockwell Automation

- Greater system reliability and increased communication speed

- More than 5,000 digital and 1,000 analog I/O

- Thirty-three individual ControlLogix subpanel assemblies were designed for retrofit into the existing panels

- Four ControlLogix PACs were used for control of the entire process line

- Complete facility control system fiber optic network design of 24-fiber trunk wiring, spanning more than three miles

- Fifty-seven individual I/O racks used to collect and control the process