Dragon Products – Cement Storage & Loadout System

Matrix PDM Engineering completed a storage and rail loadout project with Dragon Products Co. in Thomaston, Maine. Dragon Products, the only cement manufacturer in New England, had been relying heavily on truck and inefficient rail shipping in their cement plant, which slowed their shipping to Boston.

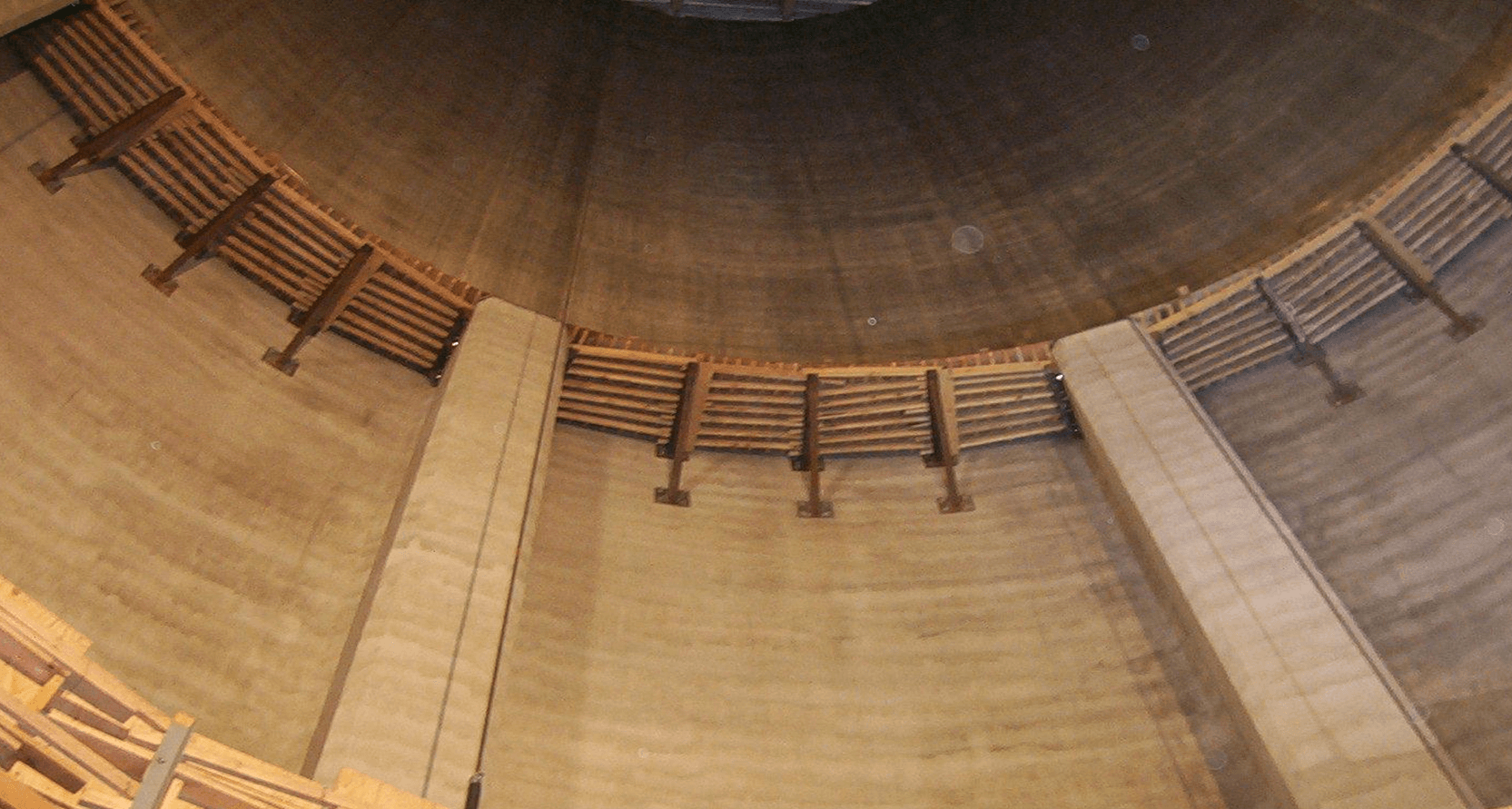

The project was completed within five months with Matrix PDM guiding the project from conceptual development to construction. The project included an 8,000 ton cement silo, an automated PLC/HMI control system, and a scale system was put into place to standardize the shipping load sizes to maximum efficiency.

The 52 foot diameter by 153 foot tall silo has an unloading system and conveyors that move processed cement through the rail car loading spout with sensors that determine the weight of the load. Matrix PDM also designed a sophisticated dust control system that removes the dust created in the pressurized pipes from the silo, filters out the excess cement, and recycles it to the silo again for shipping.

To maximize efficiency of the rail loadout, the rail track layout was designed by Matrix PDM to run beside the silo. A branch of the existing line was retrofitted to the silo for loading, which greatly streamlined the rail shipping.

Scope of Work

- Preliminary and final engineering

- Control automation design for rail/truck loadout

- Storage and rail loadout system