The Scope of Work for Designing or Expanding a Natural Gas Processing Plant

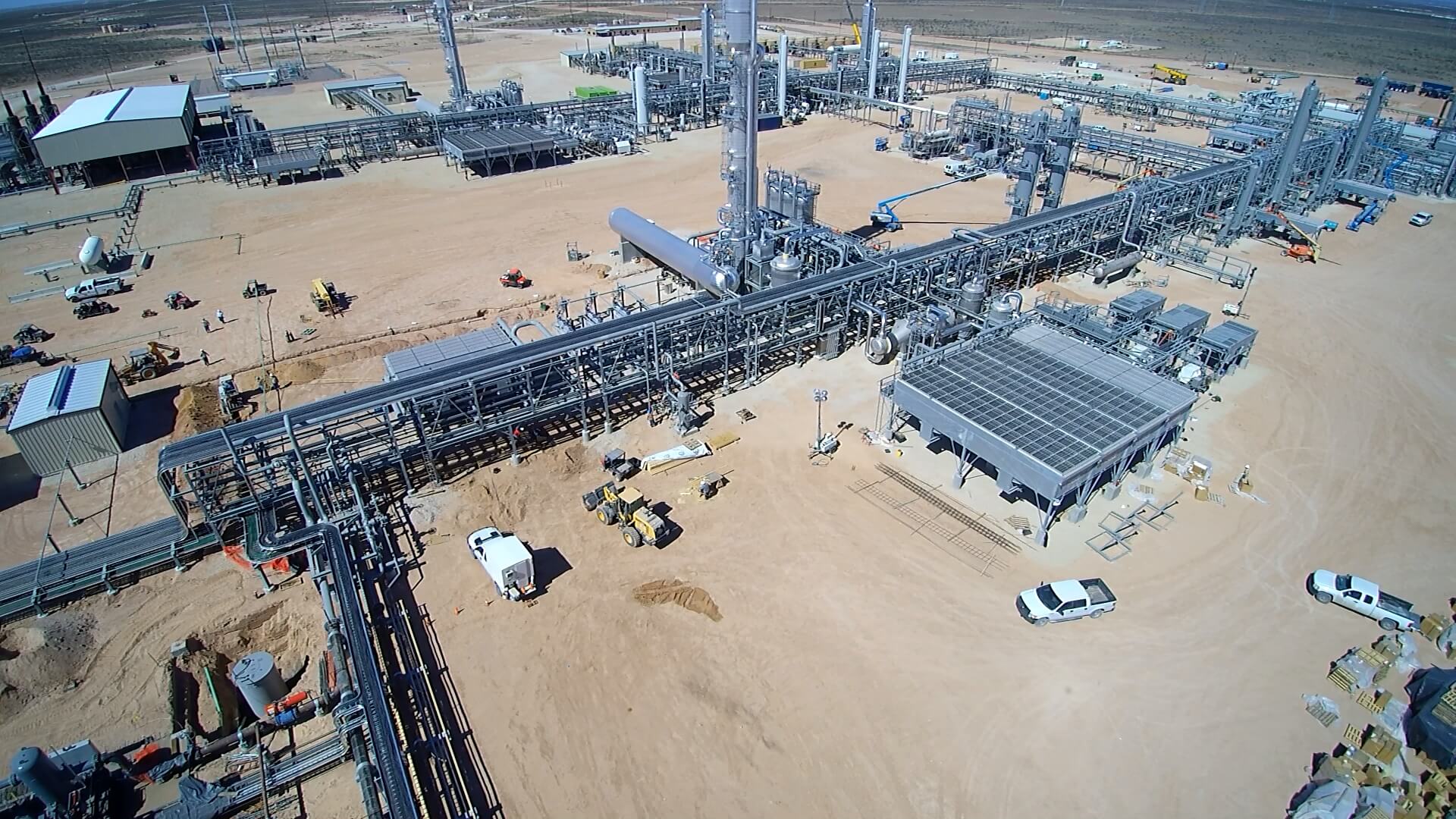

Thirty-five years ago, our company was founded as a petroleum tank provider. Since then, we’ve made multiple acquisitions, including PDM (Pittsburg-Des Moines) and more recently, the Houston Interests family of companies, that have led to the growth of our multi-discipline engineering services in terminal construction, cryogenic storage tanks for LNG, and steel plate structures as well as cyrogenic natural gas processing facilities. Recently, Matrix PDM Engineering provided the final design for engineering and construction of a 200 MMSCFD natural gas processing plant in central Texas.

After providing front end engineering (FEED) services, subsequent phases of the project included providing the balance of plant (BOP) engineering, integrating the master piping and instrumentation diagram (P&ID), purchasing engineered equipment development, project management, and assisting on commissioning and start-up activities. Additionally, the scope of work included installing a cryogenic plant with refrigeration, liquid product treating, establishing an emergency flare system and making additions and upgrades to the DCS control system.

Another project we completed was the expansion of a 60 MMSCFD cryogenic plant in northern Louisiana, where we used a combination of modular construction and traditional stick build technology to shorten the schedule and reduce risk, ultimately bringing the site to market faster. The scope of work for this particular project included installation of a glycol dehydration with BTEX unit, a slug catcher, residue compression, and inlet compression with Rockwell FactoryTalk, a manufacturing solution software.

As we continue to be listed as one of the top EPC companies in the oil and gas sector, we gain opportunities to design and construct natural gas processing plants across the country. If your company is looking to build or expand a natural gas processing plant, our team is standing by.