Confidential Client – Gas Processing Plant – Southeast Texas

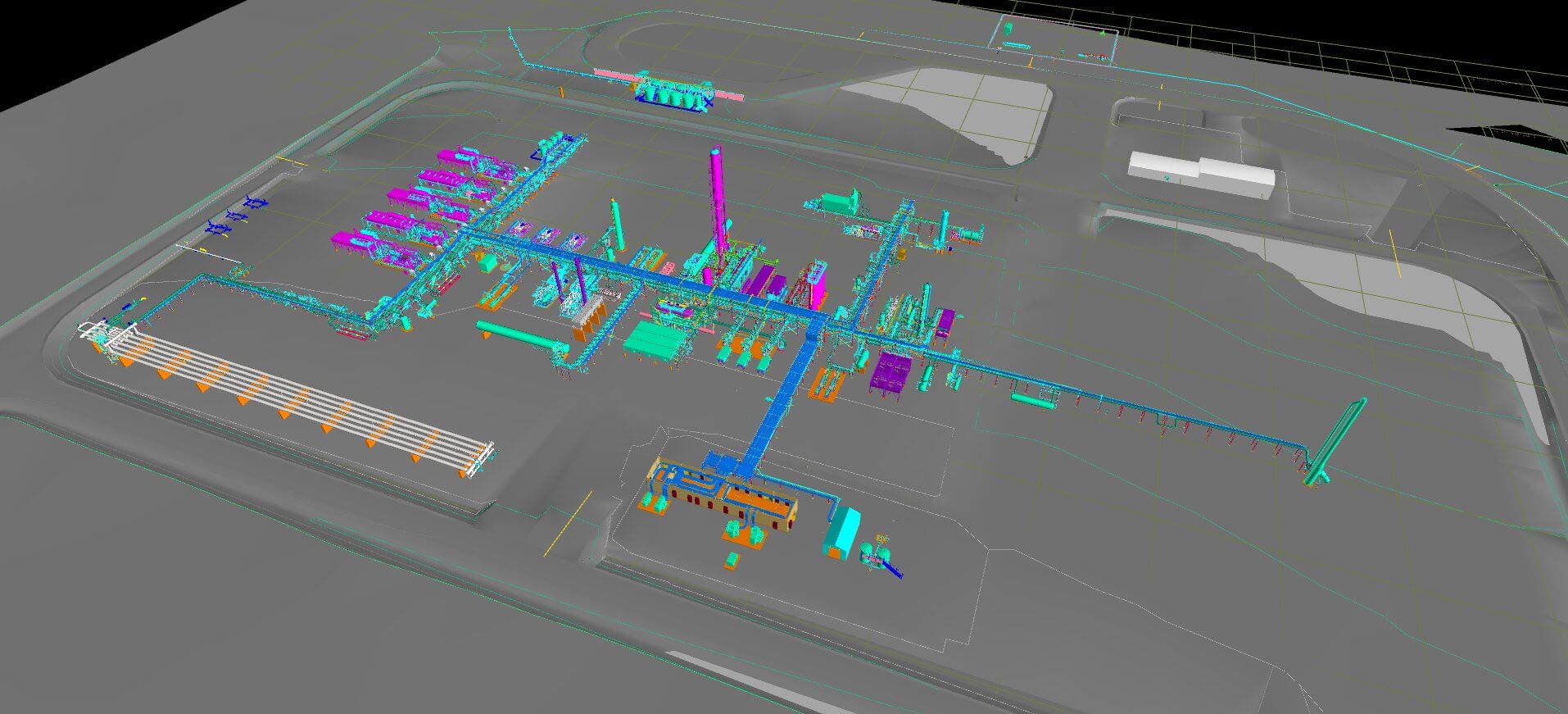

Matrix PDM Engineering provided engineering, project management, procurement, and project control services for a new gas processing facility. The facility was built to receive 200 MMSCFD of natural gas at a tie point near the southeast corner of the greenfield site. It consists of an inlet gas separator, inlet compression, a 350 GPM amine treatment process, a 200 MMSCFD cryogenic process unit including turboexpander and propane refrigeration, residue gas suction scrubber, and residue gas compression all provided by Exterran.

The facility balance-of-plant (BOP) equipment included NGL pipeline pumps, a residue gas coalescer, flare system, thermal oxidizer system, open-drain sumps, two (2) 25kV transformers, electrical distribution equipment, motor control centers, VFDs, process control system, ESD control system, and balance of plant instrumentation.

Completed in June 2019, this plant produces a residue gas product and a Y-Grade NGL product that is tied back into Train 3 through tie points located on the southeast corner of the train.

Scope of Work

- Modular design, fabrication, and construction strategy optimized schedule and reduced risk

- Modularization approach supports future expansion

- Detailed scheduling and earned value tracking for engineering and procurement

- Strong procurement coordination with multiple equipment packagers

- Cost-effective solution for switch rack/local power distribution achieved by unique electrical design

- Automation and controls design integration involved working closely with a third-party programming consultant

- Site acceptance testing was coordinated with the owner and third-party programming consultant