Confidential Client – Gas Processing Plant – West Texas

Location: West Texas

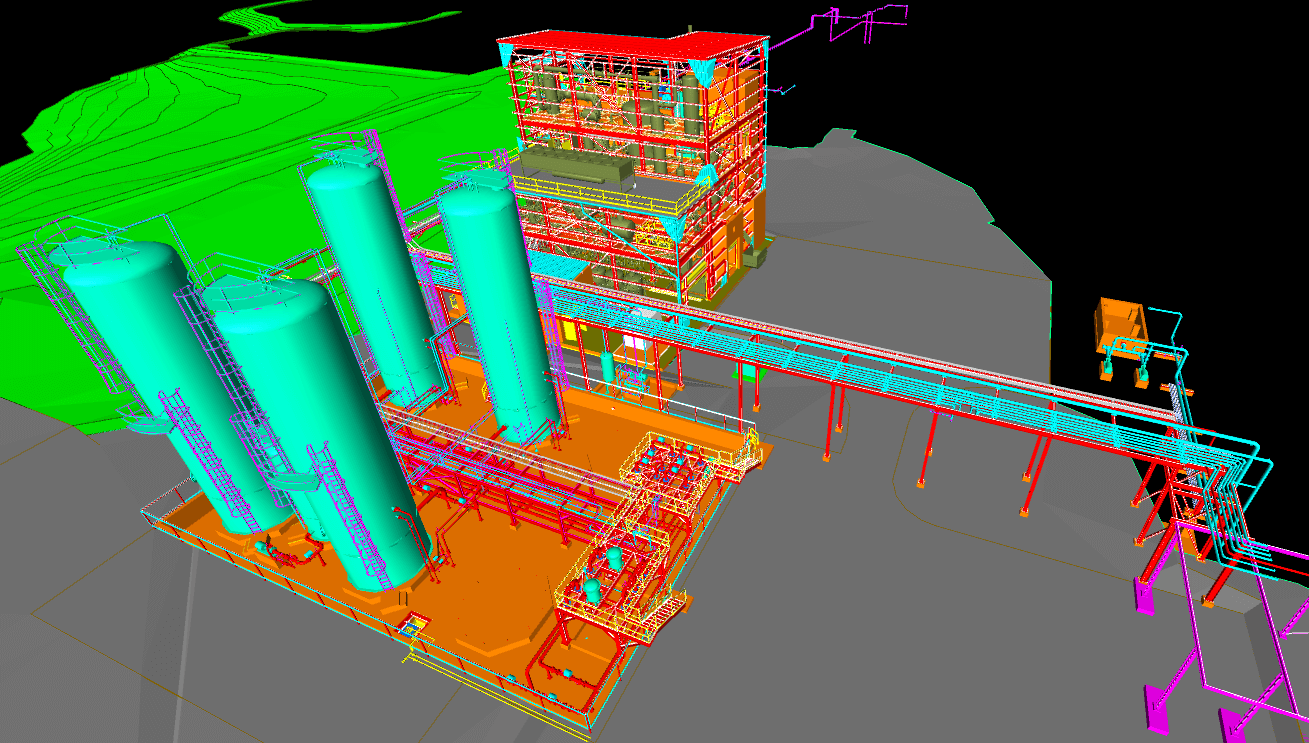

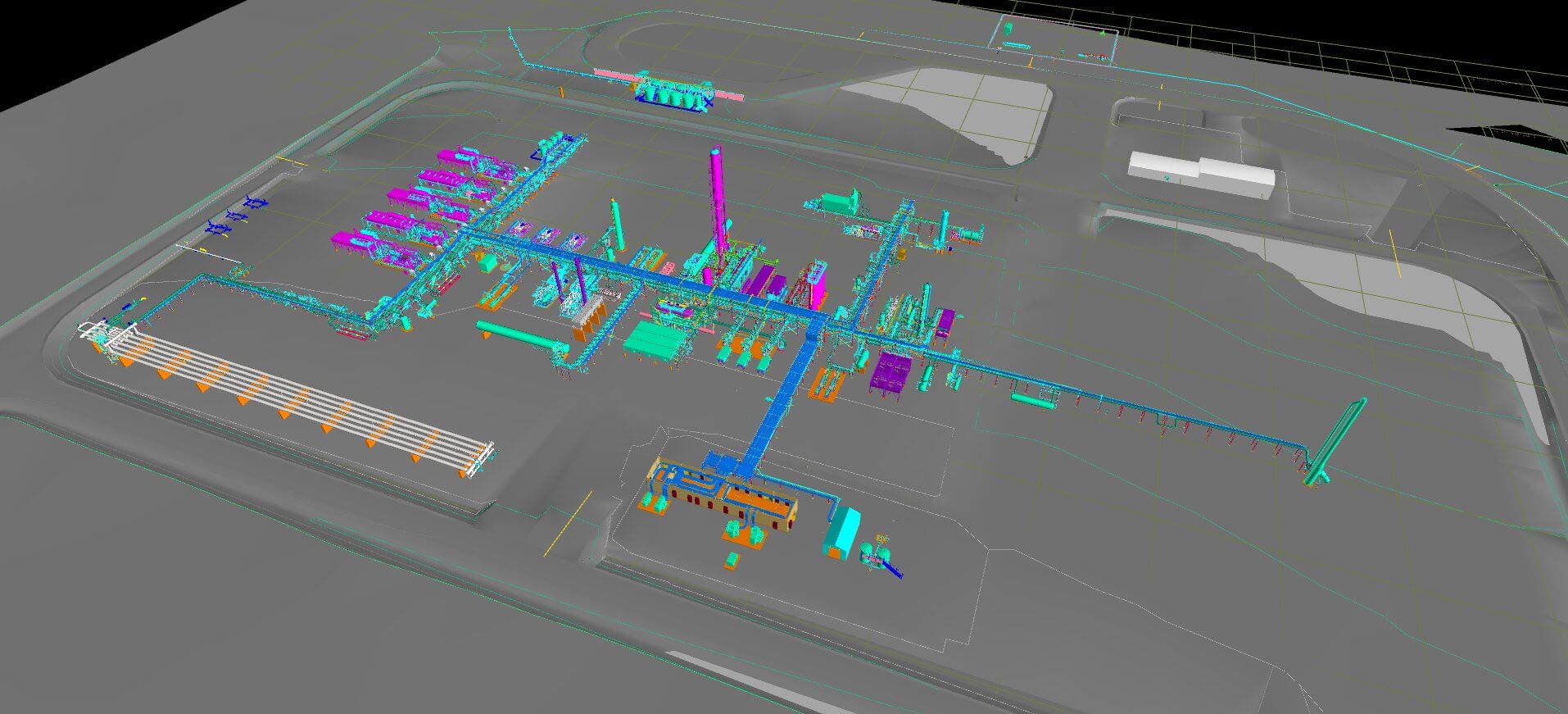

Matrix PDM Engineering, working closely with a confidential client, provided multi-discipline engineering and construction support for a 200 MMSCFD cryogenic gas plant, including a cryogenic refrigeration system, condensate stabilizer, 4,000 BBL slug catcher, heaters, TEG, thermal oxidizers, fuel gas, flare, and truck loading/unloading, and an integrated process controls system.

Matrix worked with a construction partner to develop an EPC solution while leveraging Matrix’s gas processing expertise, partnerships with key process equipment suppliers, and Matrix’s modular design approach which allowed Matrix PDM to deliver an operating facility on schedule in June 2020.

200

MMSCFD cryogenic gas plant

4000

BBL slug catcher

100%

completed on schedule

Scope of Work

- Multi-discipline engineering and construction of a 200 MMSCFD cryogenic gas plant

- Cryogenic refrigeration system

- Condensate stabilizer

- 4,000 BBL slug catcher

- Heaters, TEG, thermal oxidizers

- Fuel gas, flare, truck loading/unloading

- Integrated process controls system

- Modular design, fabrication and construction strategy optimized schedule and reduced risk

- Designed heat medium oil skid and coordinated fabrication

- Robust earned value management process, resulting in improved reporting and customer satisfaction

- Procurement coordination with multiple equipment packagers

- Automation and controls design and implementation resulted in smooth commissioning and startup