Confidential Client – Glycerin Refinery at Biodiesel Plant

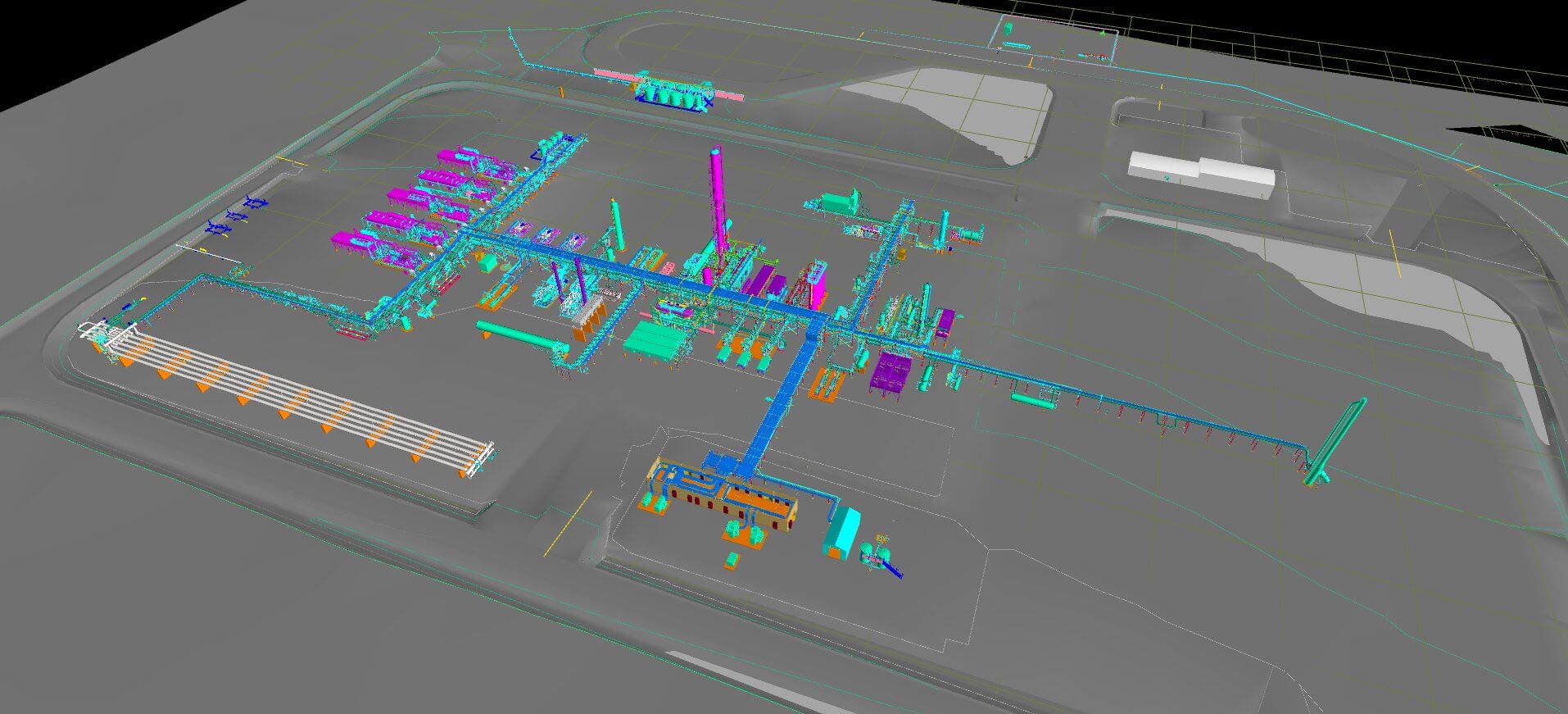

Matrix PDM Engineering provided balance-of-plant engineering for a glycerin refinery at a biodiesel plant. The new refinery refines raw glycerin from the biodiesel plant to pharmaceutical-grade glycerin.

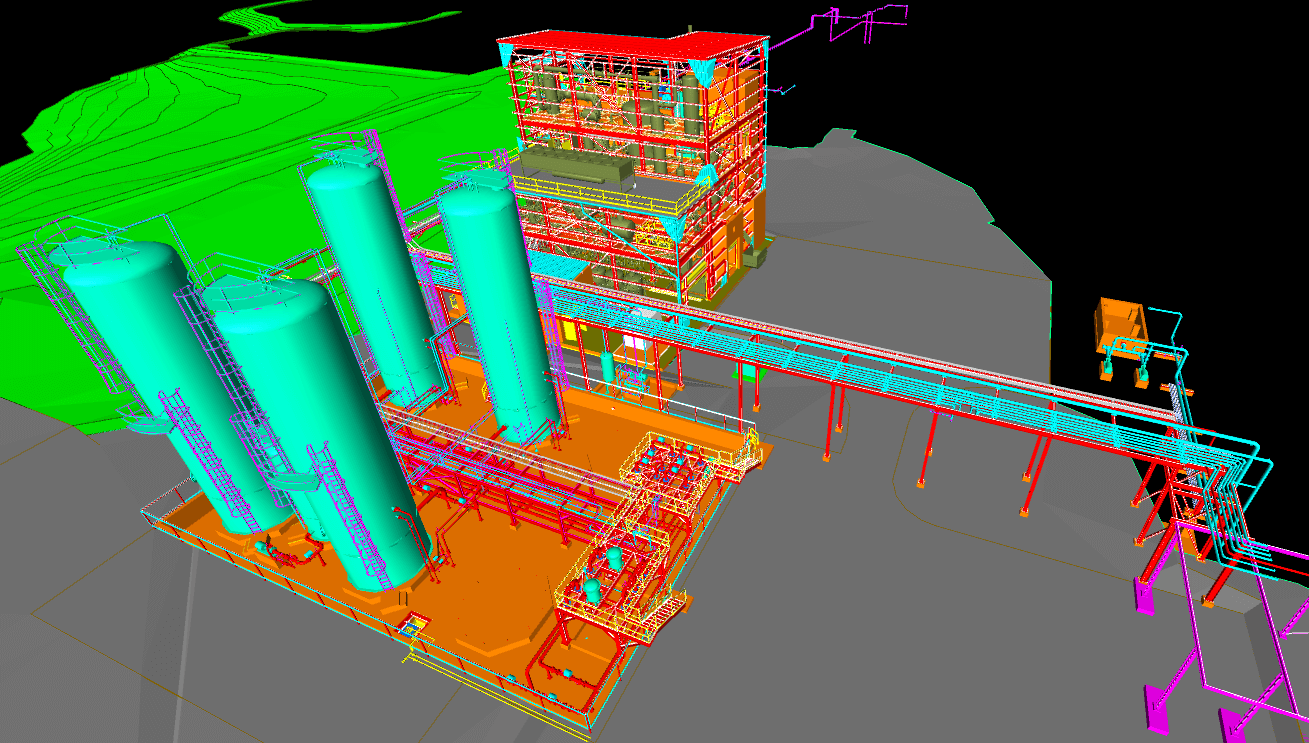

Engineering design services included the process building, a 208,000-gallon tank farm, storage buildings, refinery process cooling systems, and truck and rail loadout facilities. The structural and architectural design of the project included foundation, structural calculations, and drawings for the refining area and building. Additionally, civil site work was provided for re-routing an existing road.

Process and piping design for the facility included generating P&IDs, interconnecting piping design with isometrics, utility rack piping from the existing building to the new building, distribution of air and nitrogen, providing system, tank, skid and pump specifications, and design packages.

The electrical and instrumentation services included the layout of a new primary feed and design of I/O panel layouts, schematics, and diagrams for control systems. New transformers, panels, switchgear, and LV MCC equipment, process and tank instruments, power, and control interfaces for equipment were specified, in addition to construction plans for wiring installation.

PRINCIPAL FEATURES

• Second largest glycerin refinery in the United States

• 208,000-gallon tank farm

• Four storage tanks of the finished product

• Truck and rail loadout at 350 gpm

• Building includes an office, control, break, and locker rooms

• Fire protection and alarm systems

• Tote storage building for activated carbon totes