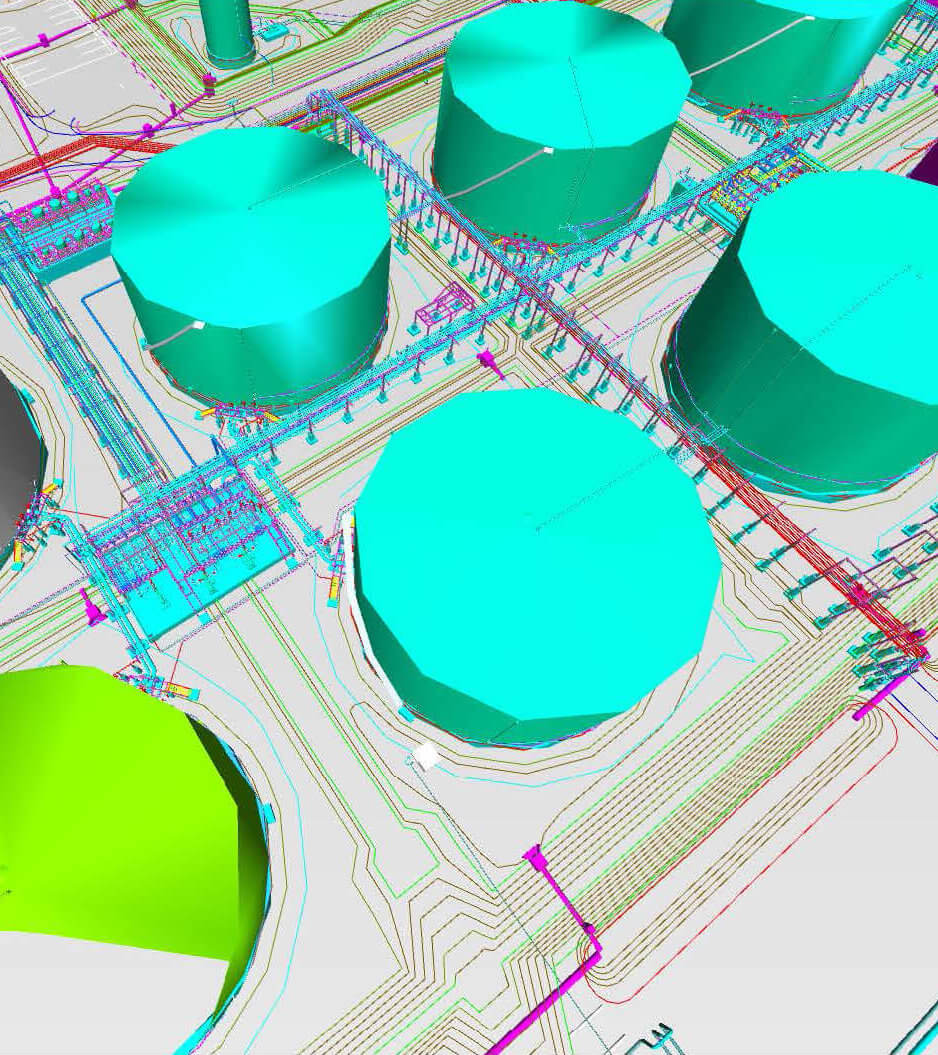

The Mosaic Company – New Wales Sulfur Melting Facility

Matrix PDM Engineering developed an engineer-led EPC strategy, leveraging proprietary melting and filtering technology, sulfur handling and storage experience, and executing a modular design, fabricating, and construction strategy to shorten the schedule, reduce risk, and reduce on-site construction.

The new sulfur melter plant will heat prilled sulfur to liquid form and mix with existing molten sulfur supply. With world sulfur markets changing, this method provides a new opportunity to ensure a more reliable and low-cost supply.

Electrical and control system scope includes design to classifications, gas sensors, 15Kv rated cable, two oil-filled secondary substation low voltage transformers, two electrical buildings, switchgear, MCCs, variable frequency drives, and uninterruptible power supply. The control system utilized one stand-alone Factory Talk View SE and one distributed client connected to the existing two FTViewSE server stacks. Automated, semi-automated or manual control functions were designed for plant equipment with automated or semi-automated functions for process streams.

Scope of Work

- 6,000-ton concrete storage silo

- Automated dual lane truck unloading system

- 500 tph conveying systems

- 165 tph reclaim and melter feed system

- 1 MMTPY Sulfur Melter

- 6% Moisture

- Less than 20 ppm solids after filtration

- 17,000 acfm exit flow rate

- SO2 outlet, wet uncorrected 5 ppmv

- H2S outlet, wet uncorrected 5 ppmv

- Rockwell automation PAX control system

- Redundant I/O communications

- Rockwell factory talk SE HMI platform with redundant networks